Page 13 - Microsoft Word - One-Report-Eng 2024 Final.docx

P. 13

Tycoons Worldwide Group (Thailand) Plc.

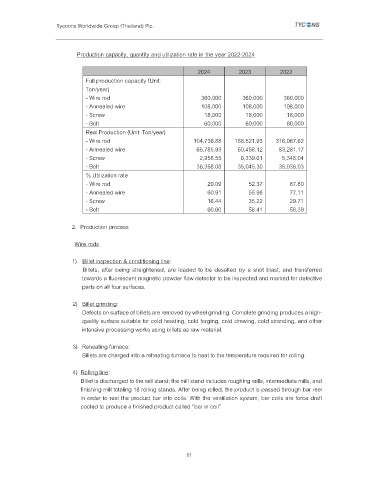

Production capacity, quantity and utilization rate in the year 2022-2024

2024 2023 2022

Full production capacity (Unit:

Ton/year)

- Wire rod 360,000 360,000 360,000

- Annealed wire 108,000 108,000 108,000

- Screw 18,000 18,000 18,000

- Bolt 60,000 60,000 60,000

Real Production (Unit: Ton/year)

- Wire rod 104,736.88 188,521.93 316,067.62

- Annealed wire 65,785.93 60,458.12 83,281.17

- Screw 2,958.55 6,339.61 5,348.04

- Bolt 36,358.08 35,045.30 35,036.03

% Utilization rate

- Wire rod 29.09 52.37 87.80

- Annealed wire 60.91 55.98 77.11

- Screw 16.44 35.22 29.71

- Bolt 60.60 58.41 58.39

2. Production process

Wire rods

1) Billet inspection & conditioning line:

Billets, after being straightened, are loaded to be desalted by a shot blast, and transferred

towards a fluorescent magnetic powder flow detector to be inspected and marked for defective

parts on all four surfaces.

2) Billet grinding:

Defects on surface of billets are removed by wheel grinding. Complete grinding produces a high-

quality surface suitable for cold heading, cold forging, cold drawing, cold stranding, and other

intensive processing works using billets as raw material.

3) Reheating furnace:

Billets are charged into a reheating furnace to heat to the temperature required for rolling.

4) Rolling line:

Billet is discharged to the mill stand; the mill stand includes roughing mills, intermediate mills, and

finishing mill totaling 18 rolling stands. After being rolled, the product is passed through bar reel

in order to reel the product bar into coils. With the ventilation system, bar coils are force draft

cooled to produce a finished product called “bar in coil”

11